Metal Stamping

Numco USA is your number one sourcing agent for custom metal stampings. We work with only the best, most capable domestic and offshore contractors to ensure that your parts and components match your designs exactly and provide the fit, form, and function you require. Our metal stamping suppliers can create new, custom tooling based on your design files.

Our single punch and progressive metal stampings can be finished with various plating options or epoxy coatings, as needed. We also offer precision machining and other secondary services to give you complete-to-print, ready-to-use parts. With our extensive manufacturing capabilities, we can do more of the work so you don't have to.

Numco USA is the sourcing agent you need for custom metal stampings. Our domestic and offshore manufacturing contractors produce high quality, high precision metal stampings that match our customers' exact design specifications, no matter how simple or complex the shape of the part.

We can deliver metal stampings in a range of materials, including steel, pre-galvanized steel, aluminum, stainless steel, and brass. Standard sheet metal and thicker materials are available, as your designs require.

Our manufacturing capabilities include both single punch stamping and progressive die stamping. Though both metal stamping methods offer a wide range of possibilities, in general, single punch stamping is preferred for larger and/or simpler parts and thicker metals, while progressive stamping is better suited to producing smaller and more intricate components from thinner materials. We will work with you, as needed, to determine the best stamping process for your project.

Single Punch Metal Stamping

In simplest terms, single punch stamping works just as the name suggests: a single stroke of the stamping press produces a single part. With the proper tooling, holes and other features can be included in single punch metal stampings without the need for additional fabrication. Complex shapes are also easily achievable through single punch stamping. However, this method is generally restricted to relatively flat or "two-dimensional" parts.

Single punch stamping is a fast and efficient method of producing parts from sheet metal. Depending on the size and shape of your parts, the design template can be "nested" on the sheet metal prior to stamping for optimum part yield and minimal material waste. Ultimately, less scrap equals a lower cost per piece. When it comes to producing the maximum number of custom metal stampings from the least amount of material, Numco manufacturing contractors are experts.

Progressive Metal Stamping

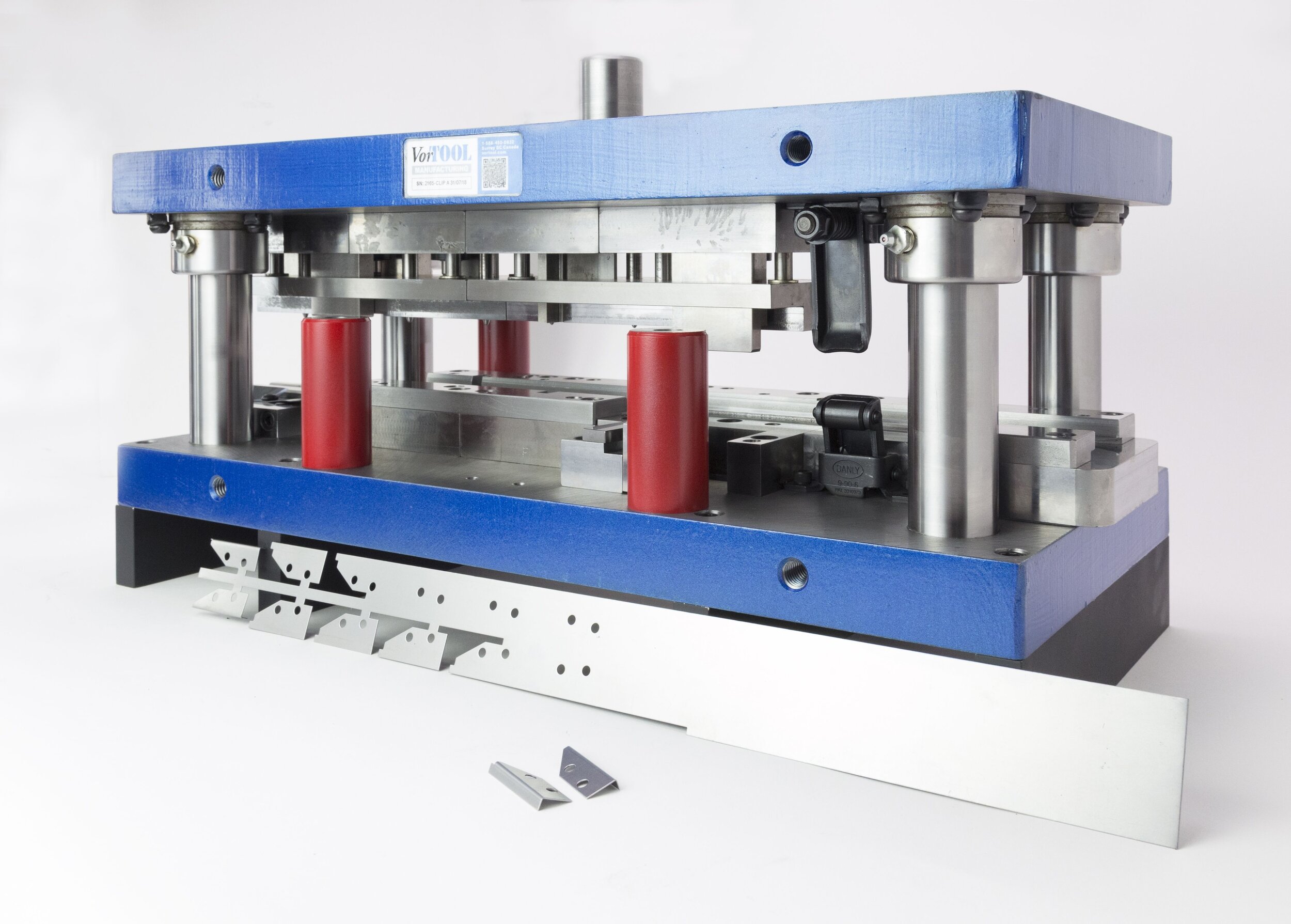

Progressive stamping incorporates numerous processes—including, but not limited to, punching, coining, and bending—to produce intricate metal parts and components. Metal strip or metal coil is fed into a stamping press that is divided into multiple "stations," each with a different stamping tool. As the material moves through the machine, the different tools stretch, cut, or otherwise form the metal into the desired shape, one step at a time.

Progressive stamping is ideal for "3-D" parts. The more complex the design, the more stations/tools required to transform the raw materials into custom metal stampings. However, because the process almost exclusively uses metal strip or coil, it is generally restricted to smaller components that can be produced from these relatively thin materials. Numco USA has the experience and the expertise to produce even the most intricate designs into highly accurate progressive metal stampings.

Contact us.

Interested in doing business with us? Please fill out the order form below and upload any product drawings, specifications or materials lists you may have. Thank you!